As foretold, the second installement in the LEGO Microscopy series has arrived.

Today we take a closer look at a part of a system that made constraction possible, and at the same time, led to its downfall. The (in)famous ball joint socket!

The original socket served as a receptacle for the ball joint itself and allowed for free poseability. It had to be durable enough to withstand the spherical rotating motion and repeated disassembly.

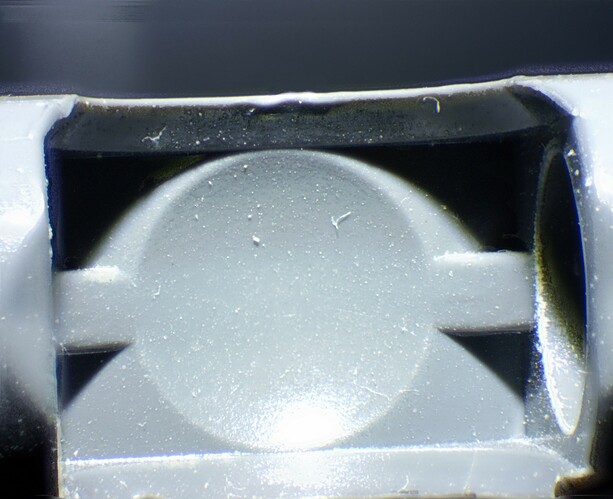

The socket was composed of two major parts namely the bed and the arcs. Let us see how the interior of these parts is designed:

The bed of the socket has a spherical depression in which the ball rests and rotates. The two slopes at the sides provide added support and prevent the ball from flying-off easily.

The two arcs hold the ball in place and provide the necessary friction to the joint. These are the parts under the most mechanical stress and usually when something on the socket fails, it is exactly this.

As you can see on this Metru socket, the edges of these arcs are worn out and deformed with long term use.

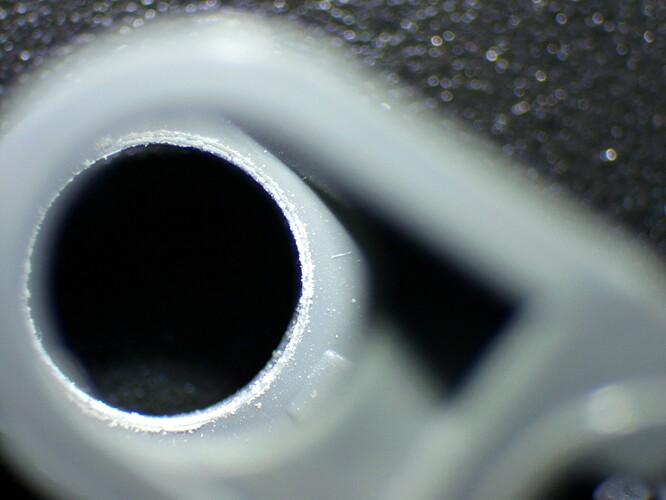

The arcs have holes inside to accomodate the spherical shape of the ball joint. The internal rim of these holes is getting milled out with repeated use, which eventually leads to the loss of friction and drooping limbs in figures.

The transversal connection of the arcs also has the concave shaping on the inside for the ball.

Injection point and the logo.

On the other side - two sets of numbers. One of them most likely position within the mold, the other perhaps the part ID.

And that is it for the old school ball joint socket!

What’s that? Did you expect some major socket breakages to appear in this topic? Unfortunatelly for you, but fortunatelly for me, I do not own a single broken Bionicle socket

The old design depicted here is simply too reliable for normal use and I have never put the new 2008 fragile design under much action at all. They can’t break if you have them in a single pose after all.

And the lime plastic? As far as I’m concerned, the claim that it is more fragile then the other colors is just a myth. I have yet to find any good evidence to validate its truth.

So despite the lime plastic becoming an inside joke in the Bionicle community, unless someone has done a thorough quantitative analysis of the socket breakages showing that the lime ones are indeed more prone to break, you should not take this claim seriosly.

I hope you enjoyed!

The plastic cracking goblin will not escape my sight!

The plastic cracking goblin will not escape my sight!